Coffee processing is a term frequently discussed in specialty coffee, and for good reason. How a coffee is processed can have a great deal of effect on the flavor and quality of a coffee, and is one of the few points of data that can tell a coffee buyer what to expect in a coffee before even tasting it.

What is coffee processing and how does it relate to flavor in your brewed cup? As with so much in the craft and science of coffee, the topic is deep, complex, and nuanced, but I'll do my best here to provide a general overview of the most popular methods in the hopes of providing a solid baseline understanding of coffee processing for any coffee lover, regardless of where you are on your specialty coffee journey.

Contents

What is coffee processing?

In the simplest terms, a coffee's "processing method" describes the techniques used by a coffee producer to isolate the coffee seed (also known as the coffee bean) from the surrounding fruit and prepare it for export and roasting.

Because coffee cherries are processed in large quantities (a single cup of coffee requires 100 or more coffee beans), producers have developed systems that isolate, clean, and dry the coffee seeds en masse. The technique a producer chooses to employ is called the processing method.

The anatomy of a coffee cherry

To some, it comes as a bit of a surprise to learn that coffee is the seed of a fruit, known as a coffee cherry. Like the common cherry fruit we all love, the coffee cherry has an outer skin that protects a juicy sweet fruit layer, with a seed in the center. If you've ever tried to pit a cherry (or other stone fruit for that matter), you'll know that the seed tends to cling to the outer fruit layer (called mucilage in coffee cherries) and can't simply be removed easily, clean and free of the fruit. Since with coffee cherries, the prize of the fruit is the seed, getting the seed free from the fruit, cleanly and efficiently, is the goal of processing.

Coffee cherries have 6 main layers of material:

1. Skin - the outer layer that protects the fruit inside

2. Pulp - a watery, sugary layer attached to the inside of the skin

3. Mucilage - a sweet, goopy layer attached to the seed

4. Parchment - a final protective layer, or hull, surrounding the seed

5. Silverskin - a light, papery skin outerlayer of the seed

6. Green Coffee Seed(s) - the coffee bean we all know and love

Almost all coffee cherries have two seeds within, with the exception of "peaberry" coffee, a genetic mutation in which only single rounded seed develops inside the cherry.

Coffee processing stages

In preparing coffee cherries for export, coffee seeds are processed through some or all of the following stages:

- Sorting: Prior to all processing methods, harvested cherries are floated in water to sort for ripeness. Ripe cherries tend to sink, while underripe cherries will float, making them easy to remove before processing.

- Depulping: In all methods other than Natural/Dry Process, the ripe whole cherries are sent through a mill that squeezes the fruit between rollers until the mucilage-covered seed pops out, leaving the outer skin and pulp behind. The seeds are then ready for fermentation, either in water or in the air.

- Fermentation: All coffees are fermented in some manner, either in water, under the sun, or with the juices of their own fruit or other non-coffee fruits. Fermentation occurs when yeasts populate and break down the sticky mucilage that clings to the bean.

- Drying: Regardless of processing method, all coffee seeds are dried to a moisture content of around 10-12% which halts the fermentation process and stabilizes the coffee seeds for milling prior to export.

- Milling: In the final stage of preparing green coffee for export, the dried seeds are sent through a mill to remove the final layer of parchment protecting the seed. Coffee seeds are also typically sorted by grade or size during milling and filled into lined jute bags for warehousing and export.

Common Processing Methods

Washed/Wet Process

Washed Process, also known as Wet Process, is by far this is the most common processing method used because of the producer's ability to control variables, the relative ease of constructing a washing station, and the dependability of quality and flavor. Historically, the washed process has been employed in regions that have ample water supply or a climate that is too rainy for sun drying, however these days, washed coffees are produced anywhere coffee is grown.

Harvested coffee cherries are floated in water to sort for ripeness and immediately depulped, removing the majority of the skin and pulp from the seed. Depulped coffee is then typically moved to fermentation tanks to soak in water for a set period of time, typically a full day. During the soaking time, naturally occurring yeasts on the fruit and in the air (sometimes commercially developed yeasts are added too), populate in the solution and ferment the depulped coffee seeds. This fermentation process releases the remaining mucilage from the seed. The washed seeds are then drained and sometimes washed again, and set out to be dried on large drying patios, raised beds, or drying machines. The producer or mill rotates the drying seeds on regular intervals to ensure even drying and prevent molding until the desired moisture level is achieved.

Chances are that Washed Process coffees are what you are most familiar with as a coffee drinker. Washed Process coffees typically have a clean and bright character, the flavor of which is primarily dictated by the variety of the coffee plant and the terroir in which it was grown.

Natural/Dry Process

In the past, Natural Process coffees were the domain of East Africa and other regions with less plentiful water supply. Today, Natural Process coffees are produced just about anywhere coffee is grown.

Harvested coffee cherries are floated in water and sorted for ripeness, then spread out on concrete patios, or preferably, on raised beds of breathable material to increase airflow around the fruit. As the coffee cherries dry in the sun for up to 6 weeks, they are constantly raked and rotated to reduce the potential for spoilage and bruising of the fruit. The sun drying process allows the fruit to naturally release from the coffee seeds, while the extended time in the cherry seems to allow the seed to soak up some of the flavor from the surrounding fruit.

Natural Process coffees typically exhibit fruit-forward flavor notes and floral aromatics due to the extended contact time with the surrounding fruit. With less control over the fermentation environment, some Natural Process coffees can have "funky" fermentation flavors, which may or may not be appealing to all coffee drinkers. Many coffee lovers cite Natural Process coffees as their "aha moment," when beginning to discover the flavor potential in coffee.

Honey Process / Pulped Natural

At the risk of over-simplifying things, it helps to think of the Honey Process as a blend of Natural and Washed processes. Commonly employed in Brazil, Honey Process has become a popular technique for producer experimentation around the world.

Harvested coffees are floated in water to sort for ripeness and like the Washed process, they are immediately depulped to remove the skin and pulp. However, instead of following depulping with a fermentation process in water, the coffee seeds are allowed to sun dry and ferment in the open air with some of the fruit mucilage still clinging to the seed. The sticky mucilage surrounding the bean is reminiscent of honey, which is where the process gets its name.

During the drying process, the mucilage begins to dry and darkens in color. As it darkens, it becomes a golden yellow color, and if left to continue to dry, the shade becomes more reddish, and eventually black. The color of the dried mucilage at the time the producer ends the drying process is often referred to as "Yellow Honey," "Red Honey," or "Black Honey."

Honey Process coffees typically have great complexity, often requiring a lighter roast so as not to obscure the delicate flavors and aromatics. Many Honey Process coffees showcase a light fruitiness with the clean and bright character of a Washed Process coffee. Some Honey Process coffees have deeper savory flavor notes, and hints of wine-like "booziness."

New & Experimental Processing Methods

Anaerobic Fermentation

If you've been paying attention to specialty coffee trends over the past few years, you may have noticed Anaerobic Fermentation as a processing method has exploded in popularity with producers and roasters alike.

Anaerobic Fermentation is more of a tweak on existing processing methods than a new method altogether. As with the Washed Process, harvested coffee cherries are placed into a water-filled container for fermentation, but in the case of Anaerobic processed coffees, this container is sealed to create a low oxygen or oxygen-free environment. The lack of oxygen in the fermentation environment encourages the population of yeasts that thrive in an anaerobic environment and discourages the growth of yeasts that thrive on oxygen. The goal is to introduce unique flavors in the coffee that would not otherwise be present in an oxygen-rich environment.

Anaerobic Fermentation typically creates bright, crisp, and clean coffees with strong fruit notes from the fermentation process.

Carbonic Maceration

A technique borrowed from the wine industry, Carbon Maceration is a processing method in which the whole harvested cherries soak in water in an airtight stainless steel barrel that is purged of oxygen as it is filled with carbon dioxide. The cherries are thought to ferment from the "inside-out" and it is said that Carbonic Maceration encourages the development of more aromatics.

Carbonic Maceration typically creates bright and wine-like coffees, with strong aromatics and notes of red fruit. For better or worse, Carbonic Maceration often results in coffees with lower acidity.

Fruit Fermentation / Anaerobic Impregnation

Like Anaerobic Fermentation, Fruit Fermented coffees are fermented in a sealed container to promote the population of yeasts that thrive in an anaerobic environment. As an added step, Fruit Fermentation (sometimes referred Anaerobic Impregnation) introduces non-coffee additives to the fermentation tank. These additions often include fruits, molasses, or spices that are grown in the same region as the coffee, such as pineapple, orange, grapes, and herbs.

Fruit Fermentation has also been experimented with Honey Process coffees, wherein the fruit is added to the coffee seeds as it is turned during the drying process.

Fruit Fermentation typically results in coffees that have pronounced fruit flavors that are instantly recognizable, due to the inclusion of non-coffee fruits. While there is some debate about whether or not Fruit Fermentation belongs in specialty coffee, there is no denying the unmistakable uniqueness of these coffees.

Coffee processing and flavor

Coffee processing methods are one of the tools at a coffee producer's disposal that can be used to modulate and highlight the flavors that - with the exception of Fruit Fermentation - already exist within their coffee. As a roaster, I tend to think of processing methods as different expressions of the same coffee, and consider it my duty to roast the coffees in such a way so that the producer's intended expression is revealed in your brewed cup.

While all coffees will express themselves in their own unique way due to their variety and terroir, here's a broad generalization of coffee processing methods and the flavors they tend to encourage:

- Washed/Wet Process: Clean and bright, retains natural acidity. This is coffee as you are likely used to tasting it, which is of course delicious!

- Natural/Dry Process: Fruity and/or floral aromatics, can sometimes be a little "funky." If you've ever had a Natural Process Ethiopian coffee, this is the poster child of this method.

- Honey Process: Delicate and complex with hints of fruit, often clean and bright, sometimes with a "winey" or "boozy" character.

- Anaerobic Fermentation: Clean and bright like a Washed Process coffee, often with the fruitiness of a Natural Process coffee. A fun and popular new method!

- Carbonic Maceration: Expressively aromatic, often floral and sometimes wine-like. Typically lower in acidity.

- Fruit Fermentation: Unmistakable aromatics and flavors of the added ingredients, but with the character of a Washed Process coffee beneath it all.

Which process is best?

This is, of course, a trick question, because there is no correct answer here. Washed Process is by far the most commonly-used processing method, with Natural Process coming in as the second most used process and Honey Process at a distant third. Experimental processes are still somewhat of a niche technique, but their popularity is growing rapidly to satisfy the increasing interest from consumers in innovation.

Just like different roast levels and coffee origins, the preferences of coffee drinkers are all across the board. My recommendation is to try a lot of different coffee and different processes and decide what you're drawn to. If you're anything like me, you'll love them all!

Purchasing coffees by process

Any specialty coffee roaster who cares about transparency will label their coffee with the processing method used to prepare that particular coffee. Not only is it preferable as a consumer to have as much information as possible about your coffee, it's also a useful shortcut to generally know what to expect before buying a coffee, and helpful to buy or avoid certain processing methods that you enjoy or dislike.

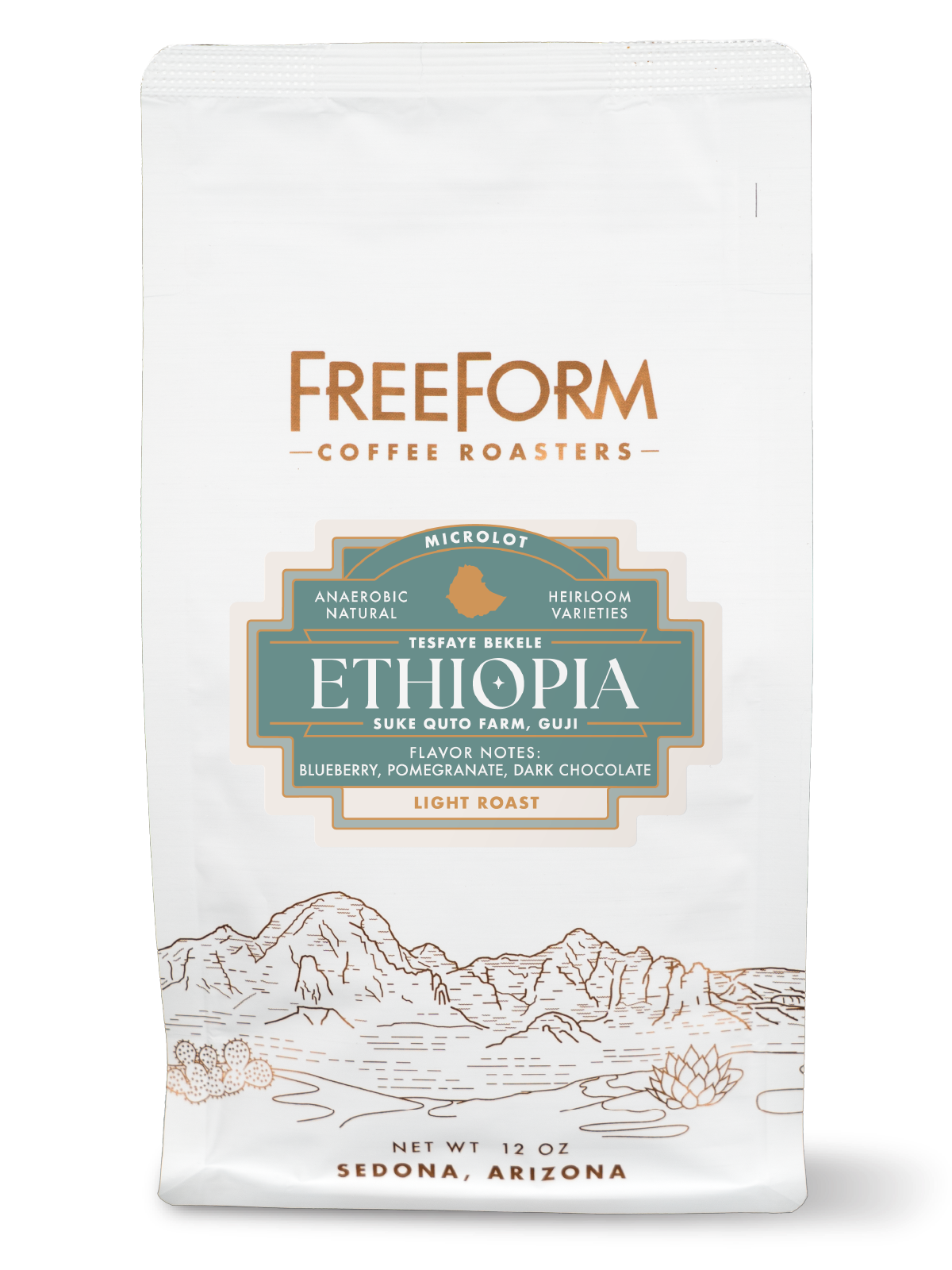

At FreeForm Coffee, all of our coffees list the processing method on our labels next to the roast level. Our website offers the option to filter our current coffees by processing method, or simply follow the links below to browse coffee by process:

- Washed Process FreeForm Coffees

- Natural Process FreeForm Coffees

- Washed and Natural Process (Blended) FreeForm Coffees

- Honey Process FreeForm Coffees

- Experimental Process FreeForm Coffees

- Decaffeinated FreeForm Coffees

In conclusion

Coffee processing is an important and exciting part of the coffee bean's journey from the farm to your cup. We're fortunate to be living in the golden age of coffee, with improvements to farming and new innovations in processing continually pushing the craft of coffee forward. Whichever coffee processing method you prefer, I hope this (entirely too long) article has helped you to better understand coffee processing and its effect on your cup of coffee.

Until next time,

-Daniel

Daniel Garland is the co-founder and head roaster of FreeForm Coffee Roasters, a specialty coffee roaster in Sedona, Arizona.

Read more

Our new quiz takes the guesswork out of buying coffee and pairs the perfect coffee just for you!

Coffee trends go in and out of style at an increasingly rapid pace, but a well-crafted blend is something that will always be en vogue. At FreeForm, we're equally pleased to offer a wide variety o...

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.